London Underground

B&B have carried out work on numerous projects on the London Underground network.The projects undertaken range from Depot improvement works removing the end gable from a complete train shed, Asbestos Removal, fabricating and erecting new structures, Decontamination to complete demolition of concourse shops whilst retaining the high street facade.

Project

Ruislip Depot

Client

LU

Description

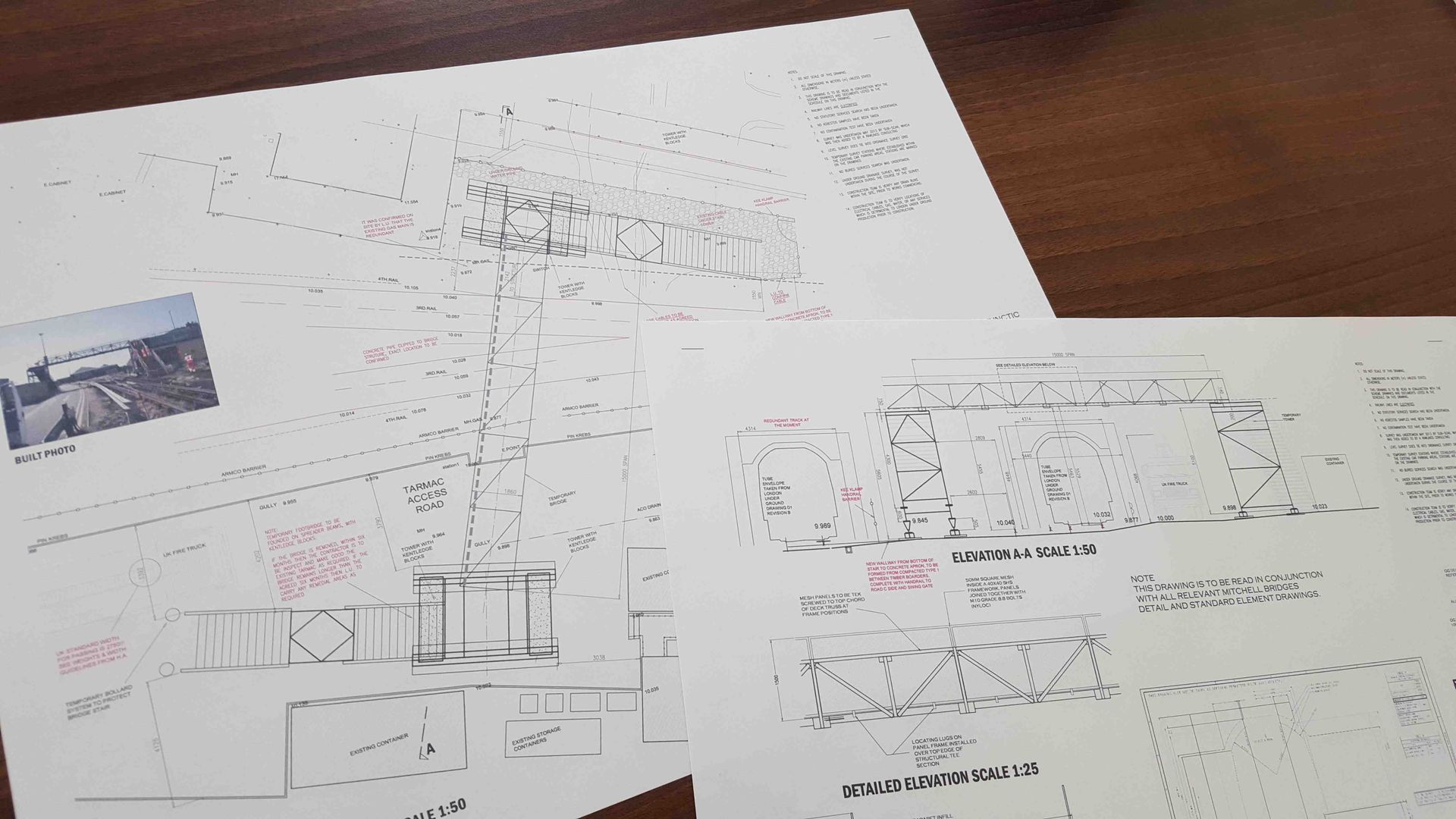

Installation of temporary foot bridge and

break out and excavation of inspection pits

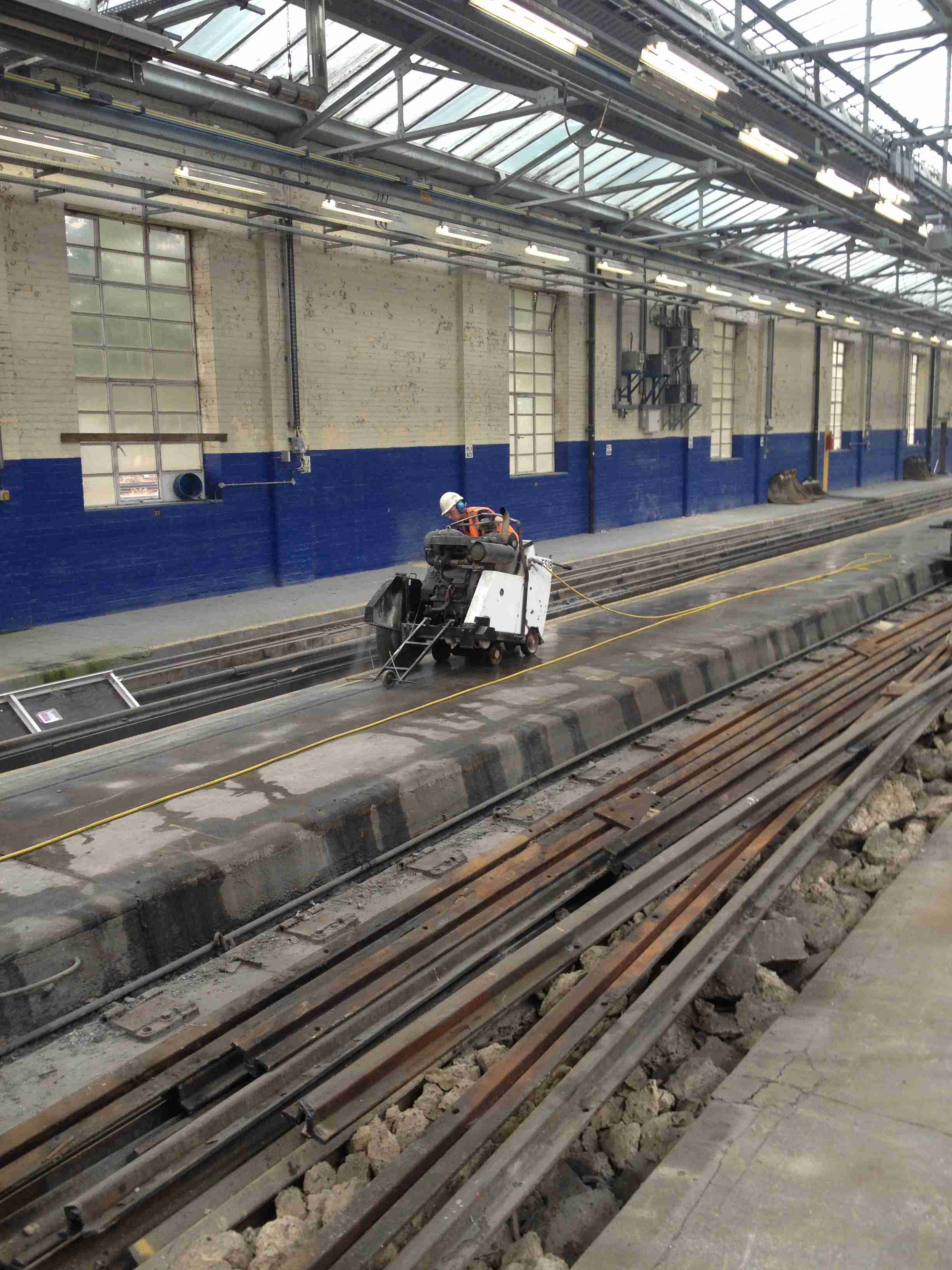

The project involved the design and installation of temporary supplies for offices and accommodation units, design and installation of a temporary foot bridge spanning over 3 No lines and a depot access road. The footbridge was then removed upon main contract completion. We also undertook the breaking out to the existing shed slab and inspection pits, as no road access was available to the structure, all plant and equipment had to be delivered by rail and the subsequent materials removed in the same manner.

Project

Shed Extension / Refurbishment.

Client

LU / KN Group

Description

Design / Installation of temporary works, Removal / Replacement of gable

and excavation of 200m of train pits

The Refurbishment of the Listed Station concourse buildings and Porte-Cochere. The installation of temporary support system (Mabey) to enable the remove of the old brick gable and installation of a newly designed gable truss.The road pits were then broken out and excavated to allow new carriage inspection pits to be cast. The station refurbishment involved the strip out of the retail unit interiors and the careful demolition of the existing concrete roof structure above leaving the listed glazed Porte-Cochere intact. This was carried out whilst the station remained operational with all deliveries / palatalized arisings being transferred at night.

Project

Ealing Comon Lathe pit.

Client

LU

Description

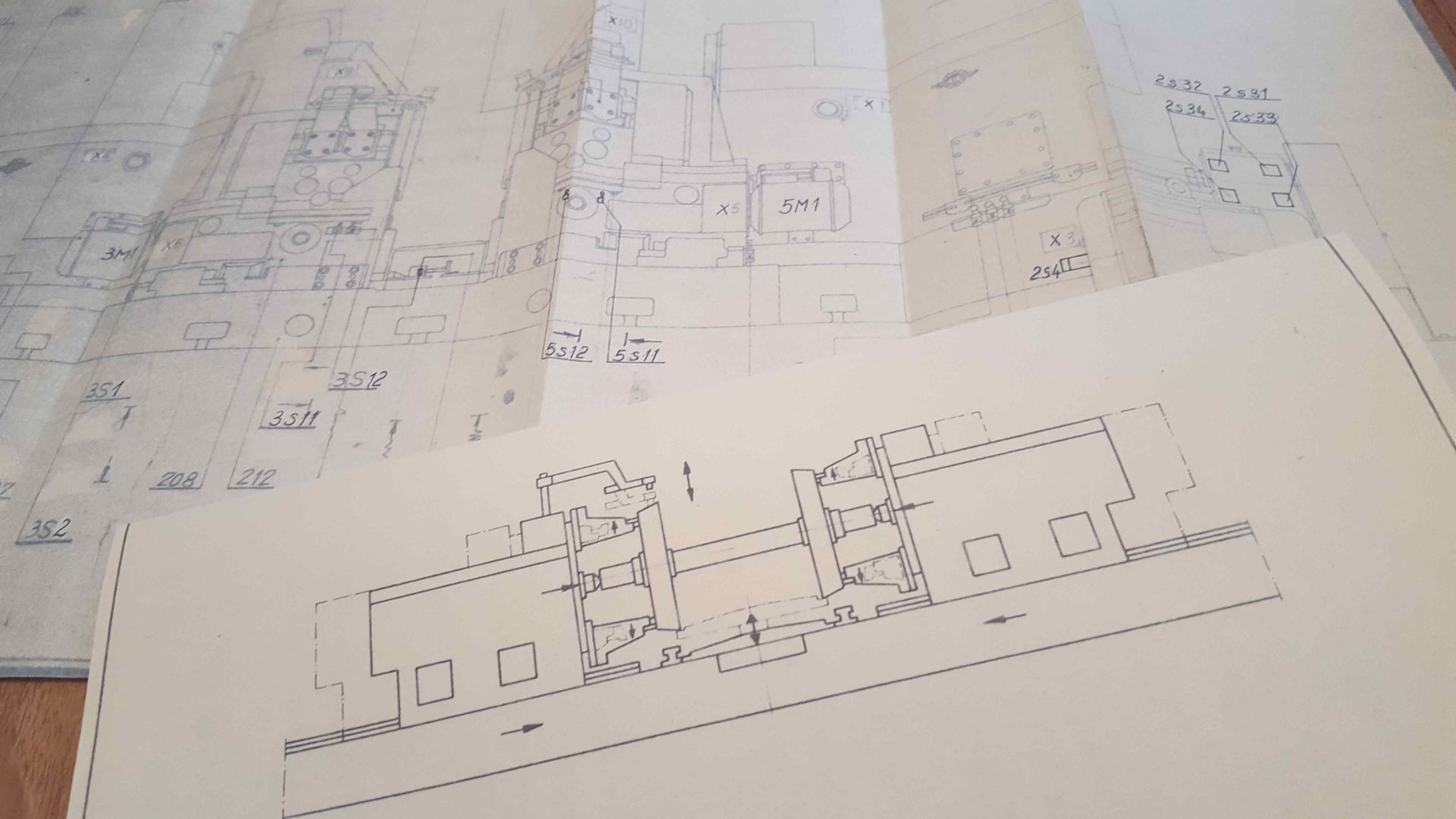

Removal of lathe units and back filling of the redundant pit including the dismantling of pillar cranes

To carry out the removal of the wheel lathe we had to utilize specialist Versa lifting equipment as there was restricted access inside the shed and due to the weight of the equipment cutting heads weighing in at approximately 22T per unit. The equipment removal involved confined spaces trained operatives and emergency rescue equipment due to the limited access for releasing the fixings and to enable the lifting out. The resulting void was back filled, compacted in 300mm layers and a 150mm concrete slab cast in situ.